Vertical Submerged Bearing Pumps

Nagle’s Single Stage Centrifugal Slurry Pump

The Nagle YWS Vertical Submerged Bearing Pumps provide slurry handling with ease of maintenance. Custom selection of impeller, casings and critical components assure maximum service life with minimum upkeep, even in the most demanding applications.

YWS Wet Pit Pump

Sizes: 1″ to 16″

Capacities: Up to 10,000 gpm

Pressures: To 130 psi

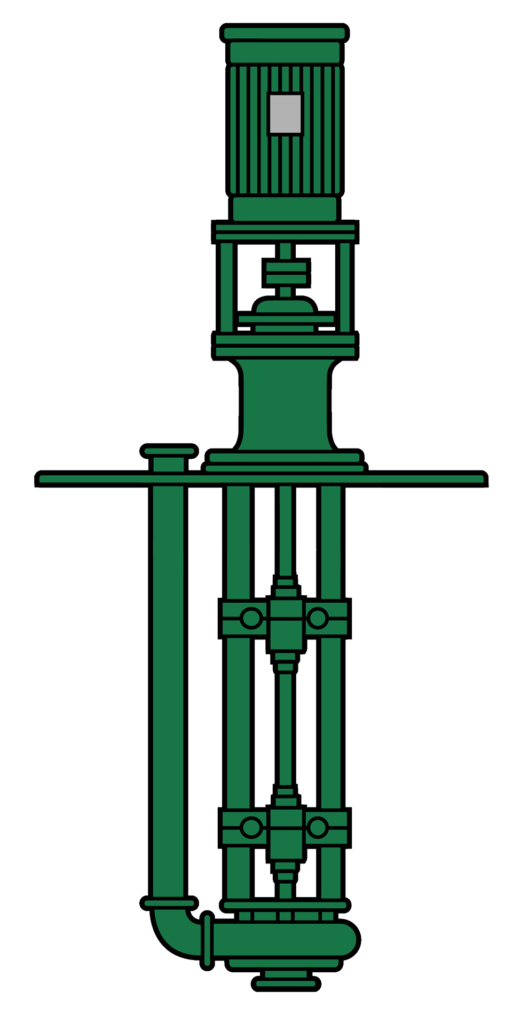

Features

- Split yoke submerged bearings facilitate replacement without pump disassembly

- Single volute, single discharge casing with progressive wall thickness maximizes service life

- Above mounting plate impeller adjustment

- Pump bearings withstand maximum thrust loads and use standard thrust motors

- All mated components register fit to ensure concentricity and speed reassembly during pump maintenance

- Standard discharge elbow and pipe eliminate proprietary parts

- Through bolt construction eliminates blind tapped holes and stud type construction

Options

- Direct coupled or V-belt drive

- Top or bottom suction

- Chemical or slurry type wet end designs

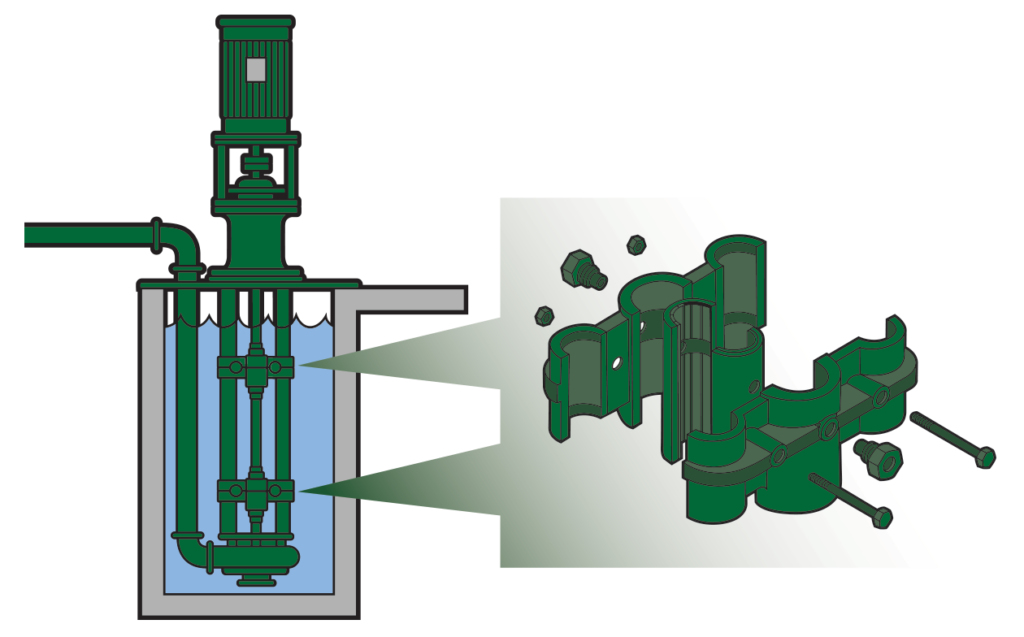

How the YWS Split Yoke Bearing Assembly Works

Conventional tapped-in and stud type bearings can be difficult to remove for routine pump lubrication, bearing replacement, and other maintenance. The split-yoke bearing housing on the YWS pump can be accessed quickly and easily–often without removing the pump.

The submerged bearing assembly’s split sleeves are clamped across the pump’s column using through bolts. These typically loosen and remove easily. In cases of age or corrosion, the bolts can still be accessed to be burned, sawed or chiseled off. This is impossible with other bearing assemblies where bearing access would require complete pump removal.

Once the through bolts are removed, bearing maintenance and/or replacement can be completed quickly, without distributing the pump casing and impeller. The open bearing arrangement permits easier inspection and complete lubrication or flushing.

Bearing material choices include micarta, ni-resist, cutless rubber, babbit, bronze, stainless steel, cast iron, teflon, or any other available material suitable for the particular application. The method of bearing lubrication can be grease, water, or lubrication by the process liquid being pumped.